If I had ten dollars for every time someone told me, “This is gonna be easy,” well, let’s just say, my bank account would be a lot fatter.

One of the main reasons I really love my job is that no two projects are the same. While I have discovered certain techniques that I can apply to one project to emulate another, typically, I have to start from square one.

Besides the fact that each client is unique, each company is speaking to an exclusive audience, each business has a particular budget, and each designer has a particular aesthetic in mind, the paper and printing industry are constantly evolving. Papers are regularly discontinued, companies merge, new practices are introduced, and there are various ways to get a similar result. It is important to be on top of your game in this field, and have partnerships with vendors who know the business and can keep you up to speed on the latest, greatest, most economical, most cutting edge options.

Take the most recent example of a stationery system…

The designer takes brightness, weight, and finish into consideration and asks me to find a paper that fits the description. I go to the rabbit hole to see if I can find a paper that fits the bill. The designer and I agree, our #1 paper choice is Strathmore Ultimate White Wove – a gorgeous, premium, bright white, uncoated sheet, with a toothy texture that comes in a variety of weights.

On to estimating… should be easy enough, right?

Well, since this IS a stationery system, our preference is to match the paper for the business cards to the paper for the letterhead. Alright, no problem… the paper comes in a 80#C, 100#C and even 110#cb and 130#cb – all in a WOVE finish – finding a match should be a piece of cake! I received instruction that we should go with a lighter weight paper on the letterhead if possible. So, off goes the first of MANY RFQ's (Request For Quotes) to our vendors:

I'll take an order of 70#T (Text) letterhead and a side of 100#C (Cover) business cards.

(Mind you, I’m estimating this with three different vendors so… I get three phone calls, letting me know…)

The papers you estimated are “mill items” (i.e. we don’t stock that paper in-house and if we order it, we have to order a bucket load). Hmmm, OK. The 100#C is not available in smaller quantities, however there's an

80#T IS.

OK, we can live with 80#T for the letterhead (and the #10 Policy envelope. The #10 Policy needs to be converted - printed first and then folded and glued - so we can save money by running the #10 with the letterhead). Sweet. Two specs down, one to go.

Our designer is adamant - the paper must be:

WOVE

BRIGHT

TOOTHY

AT LEAST 100#C or 130#C.

And… of course, it can’t be a mill item.

OK, well this paper comes in a #110cb and #130cb. That’s the same paper, right?

NOT.cb stands for cover bristol and even though it’s a wove, the finish is much smoother. I show them to our designer -

nope, not gonna work.Back to the drawing board.

After about 3 trips back and forth with paper samples, none of which fit the bill, eventually, our vendor found a 130#C, that’s not a mill item!

It’s:

AVAILABLE IN SMALL QUANTITIES

BRIGHT WHITE

TOOTHY

It’s even in the same paper family! It’s called Platinum White Wove.

Alright… bring it on!

I gingerly approach our designer and yes! finally! we found the right business card paper!! It’s thick, it matches, it’s going to be great!

We proof all our files, send the files to the printer… and we’re off and running, woooo hooooo!

Today’s the day, we get to see the proofs, we’re rolling, we’re on our way to a … screeeeeeeeeeeeeeeeeeeeeeeeching halt.

See, the quantity on these cards are relatively low, so, to save money, we asked our printer to make masters of the business cards. In addition to printing the initial set of cards with the names on them, our vendor will print additional masters (i.e extra business card "backs" only, the front of the card will be blank). Then, they store them until the cards need to be imprinted again. This way, the initial set-up fees are not included in the price when they need to be reprinted.

Well, part of that “master plan” includes cutting the masters down to a smaller size. However, if they cut them down to a smaller size, it will cause issues with the reprint. Not only does the press they selected to reprint the cards have a size limit, it has a thickness limit as well and… you guessed it (!)… the printing machinery can’t handle the 130#C we selected!!! Ay yi yi.

So now… when it comes time to do the reprints, there will be additional problems to consider. It can be handled one of two ways:

1) Either the reprints are done on a digital press – which is an issue because, due to IT’S limitations, a digital press can’t EXACTLY match the color on the front of the card (which is extremely important in branding land) OR,

2) Our vendor can store large master sheets, which limits the ability to reproduce small quantities of cards and ultimately increases the cost.

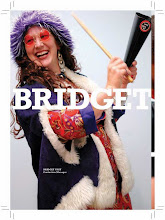

AAAAAAAAAAAAAAAAAAAAAAAAAAAAAHHHHHHHHHHHHHHHHHHHHHH! What next? The craziest thing is, this is a typical job. It’s a good thing MORRIS is the client!!